A-B-C Blog

How to Choose the Best Robotic Palletizer for Your Manufacturing Needs

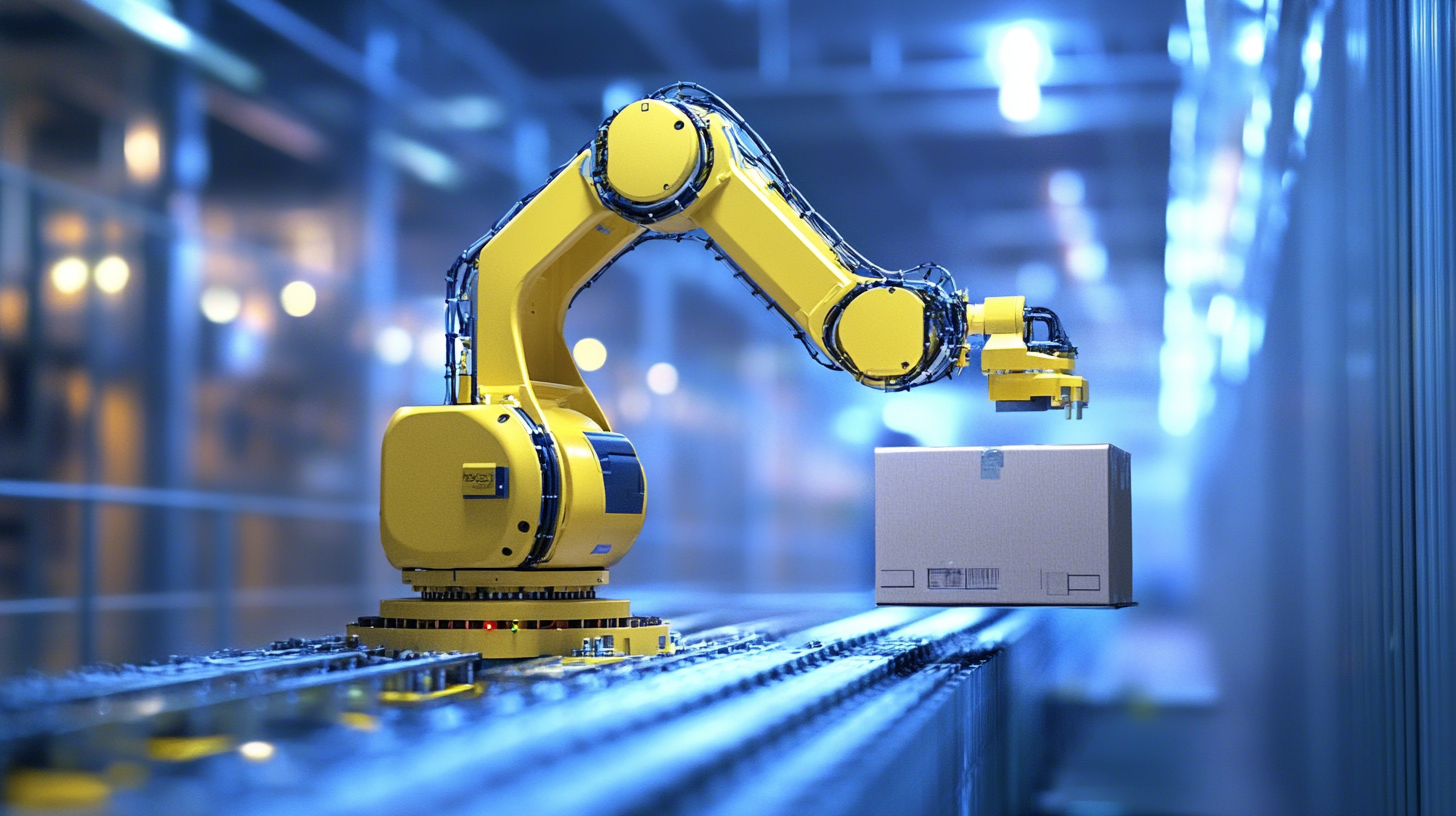

In today's fast-paced manufacturing landscape, efficiency and precision are paramount, and one of the most effective tools at your disposal is a Robotic Palletizer. These advanced machines automate the process of stacking and organizing products for shipping, helping businesses reduce labor costs and boost productivity. However, with a myriad of options available on the market, choosing the best Robotic Palletizer for your specific manufacturing needs can be daunting.

In today's fast-paced manufacturing landscape, efficiency and precision are paramount, and one of the most effective tools at your disposal is a Robotic Palletizer. These advanced machines automate the process of stacking and organizing products for shipping, helping businesses reduce labor costs and boost productivity. However, with a myriad of options available on the market, choosing the best Robotic Palletizer for your specific manufacturing needs can be daunting.

Key Considerations When Selecting a Robotic Palletizer for Your Facility

When selecting a robotic palletizer for your facility, several key considerations can help maximize efficiency and return on investment. One critical factor is the flexibility of the palletizing system. With the diverse range of products in manufacturing, a highly adaptable palletizer can handle varying sizes and weights, making it essential for sectors like dairy and beverage processing where rapid product shifts are common. Reports indicate that flexible palletizing systems are increasingly demanded by manufacturers to maintain smooth production flows while accommodating various product formats.

Additionally, the integration of intuitive programming software in robotic systems aids in reducing training time and operational costs. These advancements allow operators to easily customize workflows, resulting in significant efficiency improvements. For instance, automated palletizer systems can save up to 30% on labor costs and enhance throughput by swiftly adapting to different packaging needs. Investing in technologies that leverage artificial intelligence can boost operational speed and accuracy, catalyzing growth in sectors that prioritize food safety and product integrity.

The emphasis on automation not only helps in meeting production targets but also ensures that facilities can scale operations effectively amidst rising labor costs and market demands.

Understanding the Types of Robotic Palletizers Available in the Market

When choosing the best robotic palletizer for your manufacturing needs, it's crucial to understand the various types available in the market. The most common types include automated guided vehicles (AGVs), autonomous mobile robots (AMRs), and robotic arms. Each type serves distinct purposes, with AGVs primarily focusing on material transport, while AMRs offer more flexibility for navigating complex environments. Robotic arms, on the other hand, are particularly adept at high-speed sorting and packaging tasks.

According to recent industry analysis, the global robot market was valued at approximately USD 47.8 billion in 2024, with expectations to reach USD 211.1 billion by 2034, growing at a staggering CAGR of 16.6%. This growth is significantly driven by advancements in robotic technologies that enhance efficiency and productivity in manufacturing.

As companies increasingly recognize the value of automation, having a clear understanding of the types of robotic palletizers available can lead to better investment decisions and improved operational outcomes.

Evaluating the Cost vs. Benefits of Different Robotic Palletizing Solutions

When evaluating robotic palletizing solutions for manufacturing needs, it is essential to consider the cost versus benefits of each option. According to a recent report by the Robotic Industries Association, the investment in robotic palletizers can yield significant returns, with companies reporting an average increase in productivity by up to 30% within the first year of implementation. This productivity boost often translates to reduced labor costs, which are particularly critical given the ongoing challenges with workforce shortages in many regions.

Additionally, the operating costs of robotic palletizers generally offer long-term savings. A study by Market Research Future projected that the global robotic palletizing market is set to grow at a CAGR of 8% over the next five years, indicating a shift toward automation that many manufacturers are embracing. While upfront costs might seem daunting—ranging from $50,000 to $200,000 depending on the complexity and capacity of the system—the return on investment (ROI) can be profound. By reducing the risk of human error and increasing throughput, companies can expect to recover their initial expenses much quicker than through traditional manual palletizing methods.

Factors Influencing the Efficiency of Robotic Palletizers in Manufacturing

When choosing the best robotic palletizer for manufacturing needs, several factors can significantly influence their efficiency. One of the primary aspects is the type of robotic technology employed. With the articulated robots segment dominating the market, projected to reach USD 24.48 billion by 2030 with a CAGR of 14.4%, manufacturers must consider the unique advantages these robots provide in terms of flexibility and dexterity compared to other types like SCARA and delta robots.

Another crucial factor is the ability of robotic palletizers to integrate with existing systems. The rise in demand for efficient material handling solutions is evident as the global market is expected to grow from USD 36.77 billion in 2025 to USD 97.76 billion by 2033, indicating a significant shift towards automation.

Incorporating advanced technologies like AI for quality inspection enhances the overall productivity, reducing human error and increasing output.

The strategic selection and implementation of these robotic systems can substantially improve operational workflows, ultimately leading to a more streamlined manufacturing process.

Future Trends in Robotic Palletizing Technology You Should Know About

As the manufacturing landscape continues to evolve, robotic palletizing technology is witnessing rapid advancements that promise to enhance efficiency and flexibility on the production floor. One of the most notable trends is the integration of artificial intelligence (AI) and machine learning into robotic systems. These technologies enable robots to learn from their environment, adapt to new tasks with minimal reprogramming, and optimize their operation over time. This not only reduces the need for manual input but also significantly increases the agility of manufacturing processes.

Another significant trend is the adoption of collaborative robots, or cobots, which can operate safely alongside human workers. This shift allows for more versatile workflow arrangements, enabling human operators to focus on complex tasks while robots manage repetitive motions such as palletizing. Additionally, improved sensor technologies and vision systems are enhancing the capability of robotic palletizers to handle a diverse range of products, from fragile items to heavy loads, without sacrificing speed or accuracy. As these innovations continue to develop, manufacturers must stay informed about the latest features and capabilities to ensure they select the most suitable robotic palletizers for their specific needs.