A-B-C Blog

Exploring Innovations in Package Machine Design with 2023 Industry Trends and Data

The packaging industry is undergoing a significant transformation driven by advancements in technology and evolving consumer demands. According to a recent report by Smithers Pira, the global packaging machinery market is projected to reach USD 50 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.1%. This growth is fueled by an increasing emphasis on automation, efficiency, and sustainability in manufacturing processes, compelling innovators to rethink traditional Package Machine designs. The push for faster and more versatile packaging solutions has led to the integration of smart technology, enabling real-time monitoring and data analytics to optimize production lines.

Moreover, with sustainability becoming a focal point for businesses, the design of Package Machines is adapting to incorporate eco-friendly materials and energy-efficient components. Industry reports, such as those from Market Research Future, highlight that the shift towards biodegradable packaging solutions is resulting in a surge in demand for innovative packaging technologies. As companies seek to enhance their competitive edge in a rapidly changing marketplace, exploring these innovations in Package Machine design becomes essential for meeting consumer expectations and adhering to regulatory practices. As we dive deeper into the 2023 industry trends, it is clear that the future of packaging machinery lies in blending cutting-edge technology with sustainable practices.

Emerging Technologies Shaping Package Machine Design in 2023

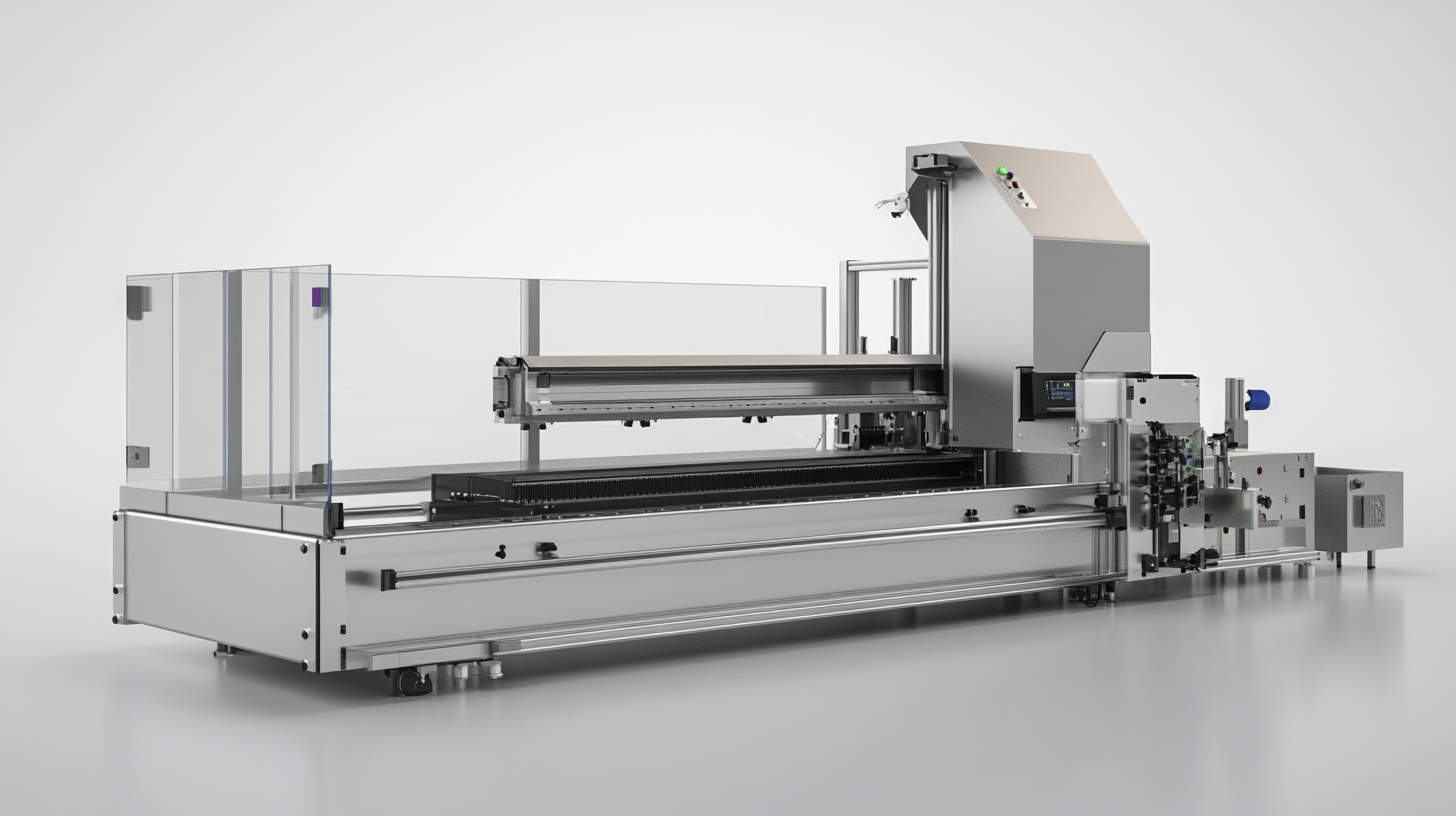

As we delve into 2023, the package machine design landscape is witnessing significant transformations driven by emerging technologies. A report from Smithers Pira highlights that automation in packaging machinery is expected to grow at a compound annual growth rate (CAGR) of 7.5% over the next five years. This surge is primarily attributed to the increasing demand for efficiency and precision in packaging operations. Smart machinery, which integrates IoT capabilities, is at the forefront of this trend. With interconnected devices, manufacturers can monitor machine performance in real-time, leading to reduced downtime and enhanced productivity. Additionally, advancements in modular design are reshaping package machinery. According to a recent analysis by PMMI, 60% of packaging companies are adopting modular systems to improve flexibility and reduce lead times. These modular machines can be easily adapted to handle different package formats, catering to the diverse needs of various industries from food and beverage to pharmaceuticals. This adaptability not only meets the rapid pace of consumer demands but also facilitates quicker changes in production lines without significant capital investment. Sustainability is another critical aspect that is increasingly influencing package machine design. The Ellen MacArthur Foundation reports that 74% of packaging executives consider sustainable designs a priority in their packaging strategies. As a result, companies are exploring eco-friendly materials and processes that minimize waste. Innovations such as biodegradable packaging machines and energy-efficient operational technologies are gaining traction, reflecting the industry's commitment to reducing its environmental footprint while meeting regulatory requirements.

Sustainability Trends Impacting Packaging Machinery Innovations

In 2023, the packaging machinery industry is experiencing a significant shift towards sustainability, heavily influenced by stricter environmental regulations and evolving consumer preferences. This trend is particularly evident in the design and functionality of liquid filling machines, which are being increasingly adapted to meet sustainability criteria. The market for liquid filling machines is projected to grow, driven by innovations in automation and material use, particularly around eco-friendly options like biodegradable and recyclable materials in packaging.

As the demand for convenient and ready-to-eat food rises, the food packaging machinery market is anticipated to expand notably, with a projected value of $22.1 billion in 2024 and a growth rate exceeding 7.3% from 2025 to 2034. This sector is actively implementing new filling technologies, including vacuum and volumetric filling methods that prioritize minimal waste and efficient resource utilization. Additionally, the rise of e-commerce continues to influence packaging designs, calling for packaging solutions that not only protect products but also align with sustainable practices.

Innovative technologies, such as FiberLean MFC in paper packaging, are leading the way in creating water-resistant and biodegradable options. This aligns with global trends of reducing plastic use and pursuing more environmentally responsible alternatives. As the packaging machinery sector faces increasing pressure to adopt sustainable practices, the incorporation of artificial intelligence for waste reduction and material sorting is becoming a pivotal aspect of industry evolution. These advancements are not just enhancing efficiency but are essential in shaping a more sustainable future for packaging overall.

The Role of Automation and AI in Modern Packaging Solutions

In 2023, the packaging industry is undergoing a transformative shift powered predominantly by automation and artificial intelligence (AI). As businesses seek to enhance operational efficiency and meet rising consumer demands, integrating AI technologies into packaging solutions has become imperative. According to a recent report by McKinsey, the global market for automation in packaging is projected to reach $5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 8.5%. This growth signifies the industry's shift towards adopting smarter, more efficient production techniques.

Automation plays a pivotal role in modern packaging design, enabling companies to streamline their processes and reduce human error. For instance, using robotic systems in packaging lines can decrease labor costs by up to 20% and significantly increase production speed. A survey conducted by the Packaging Machinery Manufacturers Institute (PMMI) revealed that approximately 60% of packaging manufacturers are actively implementing automation technologies to boost throughput and enhance flexibility in production.

Furthermore, AI is revolutionizing quality control in packaging by employing machine learning algorithms that can detect defects with greater accuracy. This results in fewer product recalls and higher customer satisfaction. According to an ABI Research report, the utilization of AI in packaging operations could reduce operational risks by over 30%, making it an essential feature for companies aiming to maintain a competitive edge in today's market. The confluence of automation and AI not only optimizes efficiency but also fosters innovation in packaging design, setting the stage for a smarter, more responsive industry.

Evaluating Efficiency: Key Metrics for Package Machine Performance

The efficiency of package machines is paramount in meeting the demands of modern industries, where speed and precision can dictate the success of businesses. In 2023, several key metrics have emerged as vital indicators of package machine performance. Among these metrics, throughput stands out—measuring how many packages a machine can handle within a specific timeframe. High throughput not only enhances productivity but also minimizes operational downtime, making it an essential element for organizations aiming to stay competitive in the fast-paced market.

Another critical metric is the Overall Equipment Effectiveness (OEE), which provides a comprehensive view of machine performance by assessing availability, performance efficiency, and quality rate. By effectively monitoring OEE, manufacturers can identify bottlenecks, reduce waste, and implement improvements tailored to their specific contexts. Furthermore, incorporating real-time data analytics helps organizations respond swiftly to performance anomalies, facilitating proactive maintenance and ensuring machines are running at optimal efficiency.

Lastly, energy consumption is emerging as a significant factor, particularly as sustainability becomes a higher priority for businesses. Package machines that operate with lower energy usage not only contribute to cost savings but also align with the broader goals of reducing environmental impact. By focusing on these key metrics in package machine design, manufacturers can harness innovations that optimize performance, drive efficiency, and support sustainable practices in an ever-evolving industrial landscape.

Future-Proofing Designs: Adapting to Changing Consumer Demands

The landscape of machine design in packaging is evolving rapidly, driven by changing consumer demands and competitive pressures. In 2023, we see a noteworthy shift towards designs that are not only efficient but also adaptable to the unpredictable nature of market needs. Companies are investing in flexible manufacturing systems that enable quick adjustments to machinery settings, allowing for variations in package sizes and materials without extensive downtime. This innovation is essential for businesses that wish to remain agile and responsive to consumer preferences.

Moreover, sustainability is a key factor influencing design adaptations. With consumers increasingly prioritizing eco-friendly packaging, machine designs are being reimagined to accommodate sustainable materials and minimize waste. This has prompted manufacturers to explore biodegradable options and efficient production processes that reduce the carbon footprint. By embracing these sustainable practices, companies not only cater to the ethical considerations of modern consumers but also ensure their machinery remains relevant in an eco-conscious marketplace.

Additionally, advancements in technology are further driving the need for future-proof designs. The integration of smart technologies, such as IoT and AI, in packaging machines enables real-time monitoring and predictive maintenance, reducing the likelihood of breakdowns and ensuring continuous operation. This tech-savvy approach allows design teams to create machines that can evolve alongside consumer trends, ensuring they continue to meet and exceed market expectations. As we move forward, the focus will be on creating versatile packaging solutions that are ready to adapt to the ever-changing landscape of consumer desires.