A-B-C Blog

Comprehensive Insights on Industrial Packaging Machines for Global Buyers

The global industrial packaging machines market is thriving due to the rapid growth witnessed in efficient packaging solutions for various industries. As per a recent report published by Grand View Research, the industrial packaging machines market is expected to be worth USD 63.67 billion by 2025, at a CAGR of 5.5%. The major driving factors besides improvements in sustainability and lowering operational costs, which are prompting manufacturers to invest in advanced packaging technologies, are competitiveness among businesses and necessity for operational efficiency through automation and smart technologies in the packaging processes.

The demands of e-commerce have added further impetus toward the development of innovative industrial packaging solutions, which ensure security for the product and provide a good experience for the consumer. The International Packaging Association emphasizes that companies are increasingly using automated packaging lines to manage the growing product volume and variety, and thus improve production speed. The ubiquity of Industry 4.0 provides industrial packaging machine manufacturers increased opportunities to integrate IoT capabilities for real-time monitoring, data analytics, and improved supply chain management. This extensive report on the industrial packaging machines market equips global clients with the information they need to make informed purchasing decisions.

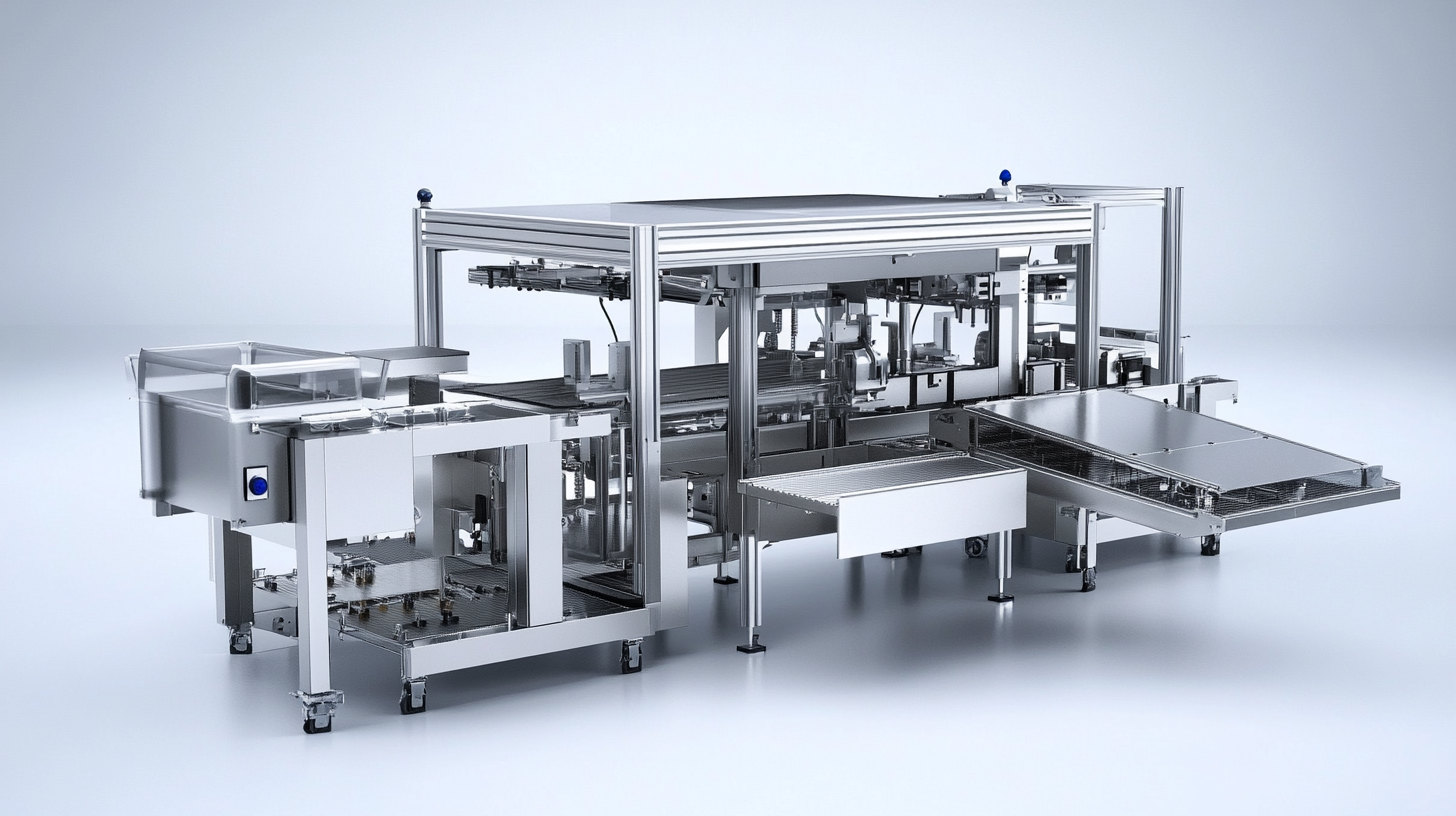

Key Features of Modern Industrial Packaging Machines

In the modernizing global packaging industry, modern industrial packaging machines are an area of intense interest to the manufacturers for the efficiency and innovation it promises. The Vietnam International Print and Packaging Industry Exhibition recently opened its doors, emphasizing the importance of these machines for effective production. This exhibition is providing a platform to showcase the newest technology set to enhance the efficiency of packaging processes and reduce operational costs, critical performances for this highly competitive market. The most important characteristics of modern industrial packaging machines include automation, flexibility, and higher accuracy. Automation is the primary feature that reduces the human intervention in a packing line thereby increasing speed and consistency in packaging lines. The new age machines embedded with modern-day sensors and software can be easily fitted into different shapes and sizes of packages, giving their customers the flexibility in keeping all kinds of today's needs under consideration. Other features of precision engineering will ensure secured and beautiful packaging that would compliment shelf appeal while reducing wastage from defects. Sustainability is becoming a buzzword with especially a lot of increasing consumer interest in such concerns, as several manufacturers had even made green or eco-friendly materials and energy saving-their designs of machines. This also encourages consumers' interests as it corresponds with the world's effort of lessening the effects of environmental destruction. Therefore it is very important, as really major trade exhibitions like the Vietnam International Print and Packaging Industry Exhibition highlight, understanding the basic features for global buyers who are in search of future investment into industrial packaging.

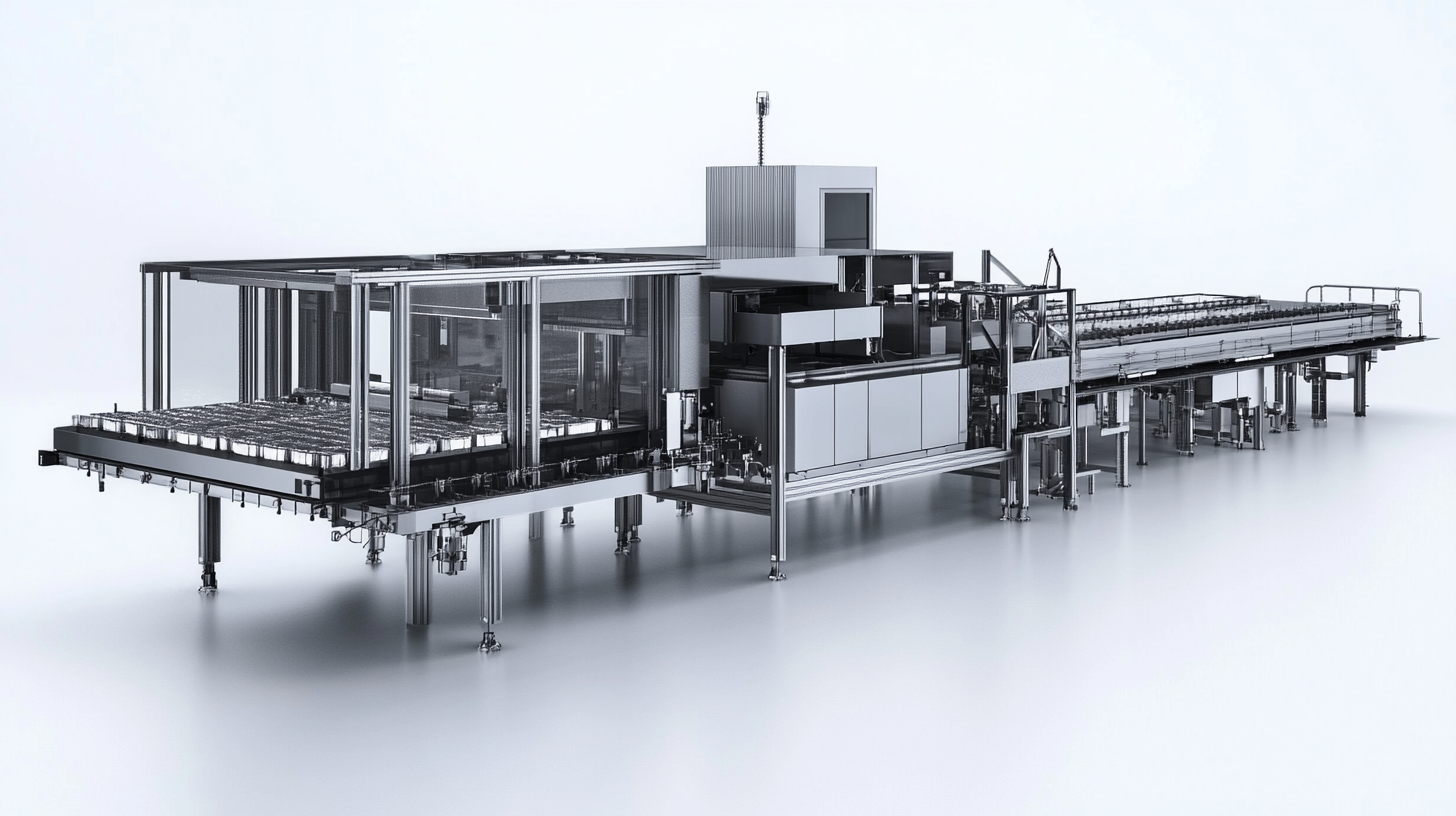

Understanding Different Types of Packaging Machines and Their Applications

Industrial packaging machines are invaluable in today's modern picture of manufacturing and distribution. The various types and usages of packaging machines are, however, known to global buyers to be able to make an informed decision about optimizing efficiency and cost. According to MarketsandMarkets, the worldwide market for packaging machinery was estimated to expand from $42.56 billion in 2021 to $56.77 billion by 2026, with an anticipated compound annual growth rate (CAGR) of 5.9%. The driver for this growth is the increased need for throughautomated packaging machines across different industries, including foods and beverages, pharmaceuticals, and consumer goods.

Filling machines are an important sector of the machines that deal with packaging products for the food and beverage industry. These machines would carry out accurate filling of products into containers, reducing the amount of waste produced as well as improving productivity in general. For instance, the food packaging industry alone accounts for approximately 40% of the total packaging machinery market. Important as these machines are as they meet consumer needs, they must be equipped to cater to the stringent regulatory standards as well. Automated packing machines, which facilitate efficient packing products into boxes or pallets, are on the rise and remarkable because of their capability to cut labor costs while retaining speed and precision in processing.

The latest buzz in environmentally friendly packing is the special machine development work which would facilitate easy handling of all sustainable packaging materials. According to the International Packaging Institute, the study shows that around 75% of consumers worldwide are willing to pay top dollar for sustainable product packing, which puts pressure on manufacturers to change their processes. Advanced packaging machines today come up with a digital technology that make machines more usable and also gets integrated for monitoring and quality control to make sure that companies meet the sustainability goals while running with production demand. With the evolution of the packaging scene, businesses would find that being in touch with the different types of industrial packaging machines and applications is the way to key the competitive advantage over others in the global market.

Factors to Consider When Purchasing Industrial Packaging Equipment

All these facts are essential to selling productions and turning in the profits for a company when one-step forward industrial capsulation equipment. Smithers Pira reports that according to projections, the global market for packaging machinery is expected to reach $63 billion by 2024 , reinforcing the necessity for choosing machines that will meet specific production requirements.

One major point that comes up when packaging material is being discussed is how different locations require different handling applications regarding machines for plastics, glass, or metals. The last research done by the Research and Markets indicates that flexible packaging is one of the segments growing at a swift pace, and it is expected to contribute nearly 30% of the total packaging in the market by 2025. This is why the consumers need to query whether the desired machine will allow the processing of numerous packages and materials, per current styles and demands.

Another essential factor for consideration is whether the machines will fit into an already existing production system. Such integration will reduce the number of hours lost at the production line as downtime, thus improving productivity. In the same vein, there's suggestion from this report that such converted automation processes for packaging are growing, so prospective customers must assess the extent of automation with which the offered equipment is compatible with their production workflows. Also, energy consumer-friendly usage has been gaining ground because companies have to minimize costs on their operations while abiding by more stringent environmental laws. In fact, packaging machinery that employs energy-efficient technologies can result in savings of up to 30% on energy costs, as indicated by a recent energy efficiency study conducted by the U.S. Department of Energy.

Potential consumers must take this holistic consideration when evaluating their industrial packaging equipment. By carrying all considerations of material compatibility, integration scalability, and energy efficiency, a company would have good grounds to make an informed decision toward better packaging processes and future sustainable business growth in a competitive market.

Latest Trends and Innovations in Industrial Packaging Technology

The industrial packaging scene has undergone stupendous trends and innovations, especially in the fields of liquid packaging systems and cannabis packaging. The flexible packaging solutions have proven increasing demand due to the fact that the liquid bag packaging market alone was worth almost $101 billion in 2023, and it is anticipated to grow at a CAGR of 5.1% until 2032. Advanced materials such as plastics and laminates are used in liquid packaging, which offer better protection and convenience for transporting liquid products. The above advancements not only provide solutions for global trade but also meet the ever-increasing demand for fast-paced logistics.

On the other hand, the cannabis packaging market seems to be gaining traction, estimated at $2.2 billion by 2024 with a forecasted 17.4% growth rate from 2025 to 2034, owing to consumers and producers' rising preference for eco- friendly and sustainable materials-a larger trend across the packaging industry toward sustainability. Manufacturers are thus responding by designing packaging solutions to meet regulatory requirements and appeal to environmentally conscious buyers.

Industry events such as the recent packaging design seminar in Longgang show the continued evolution and cooperation among practitioners in the printing and packaging industry. The impact of urbanization on industrial practices continues to shift the decision-making of packaging manufacturers towards innovative practices that accommodate both functionality and ecologically responsibility. Staying ahead of these trends is the primary importance for the global buyers as far as staying one step on the competitive edge in industrial packaging technology is concerned.

Benefits of Automation in Industrial Packaging Processes

Each process of packaging in industry is automated that transforms the manufacturing arena from a myriad benefits to other sectors. Consequently, most organizations opt for an automation process where efficiency is enhanced and labor costs are reduced. In this regard, the company could introduce automated processes to minimize human error and speed up the entire process so as to avail increased production at a rate at which many consumers can be met.

Comprehensive market surveys indicate the magnificent curve, along which the industrial packaging is heading, and projections for future periods forecast the market to take a major leap forward because of the advancement of technology. The entire industry of industrial packaging will cross a figure of $68.7 billion in terms of worldwide sales, by 2024, and this figure is, primarily, being buoyed by the explosive growth in e-commerce and logistics. This advancement gets its backing from automation technologies that facilitate seamless operations, from packing to shipping, reinforcing the sustainability and traceability of products within the supply chain.

In addition, the wide variety of different types of packaging from which raw materials come, including plastics, papers, and metals, is increasingly becoming important in the development of this industry. Moreover, specialist packaging products such as drums, IBCs, and pallets can be made exclusively for given industries and therefore have a better performance within the autodesking system. This is sure to mark an era whereby, as changes take place within the market, automating packaging will contribute to the future of operations in manufacturing plants.