A-B-C Blog

The Complete Guide to Mastering Food Packaging Machine Selection and Usage

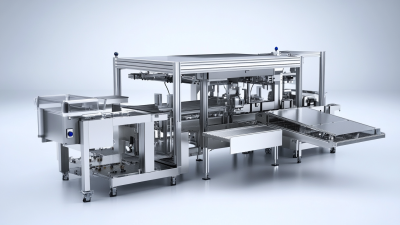

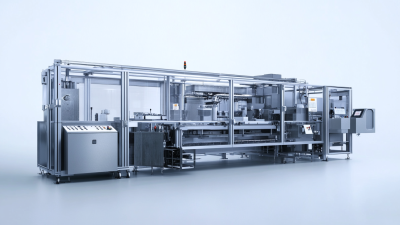

In the fast-evolving landscape of the food industry, selecting the right Food Packaging Machine is crucial for maintaining product integrity, optimizing efficiency, and meeting consumer demands. According to a report by Mordor Intelligence, the global food packaging machinery market is expected to grow at a CAGR of 5.6%, reaching $42.78 billion by 2025. This growth is driven by increasing consumer preferences for convenience and the rising need for sustainable packaging solutions. As food manufacturers navigate this dynamic market, understanding the various types of packaging machines, their functionalities, and the latest technological advancements becomes imperative. This guide will provide a comprehensive overview of food packaging machine selection and usage, empowering industry professionals to make informed decisions that enhance their operations and contribute to a sustainable future.

The Importance of Food Packaging Machinery in Enhancing Shelf Life and Reducing Waste

Food packaging machinery plays a critical role in enhancing the shelf life of products and minimizing waste in the food industry. Effective packaging not only protects food items from environmental factors such as light, moisture, and air but also extends their usability. Innovations in packaging technology, such as vacuum sealing and modified atmosphere packaging, have been developed to slow down the spoilage process, ensuring that consumers receive fresher products. With the right machinery, businesses can maintain product quality while satisfying consumer demands for nutritional value and safety.

Food packaging machinery plays a critical role in enhancing the shelf life of products and minimizing waste in the food industry. Effective packaging not only protects food items from environmental factors such as light, moisture, and air but also extends their usability. Innovations in packaging technology, such as vacuum sealing and modified atmosphere packaging, have been developed to slow down the spoilage process, ensuring that consumers receive fresher products. With the right machinery, businesses can maintain product quality while satisfying consumer demands for nutritional value and safety.

Additionally, investing in high-quality food packaging solutions significantly reduces waste. By utilizing equipment that provides better seals and barrier properties, companies can prevent spoilage during storage and transportation. This is particularly vital in a world where food waste is a growing concern. Adopting efficient packaging practices not only creates economic benefits for businesses but also contributes to sustainability efforts by lowering the amount of discarded food. As the industry continues to evolve, understanding the importance of advanced packaging machinery is essential for companies aiming to enhance their product durability and minimize waste.

Key Considerations for Selecting the Right Food Packaging Machine for Your Business

Selecting the right food packaging machine is crucial for businesses aiming to enhance efficiency and product safety. With the global smart vending machine market projected to grow from $11.47 billion in 2025 to $36.89 billion by 2032, at an annual growth rate of 18.2%, the demand for robust packaging solutions is clear. Companies must consider factors such as machine reliability, product compatibility, and ease of use to meet evolving consumer expectations.

**Tips:** When evaluating options, prioritize machines with advanced sealing technologies that not only extend shelf life but also reduce food waste. Additionally, consider the level of automation that aligns with your operational efficiency goals.

Another significant aspect to assess is compliance with food safety standards. Machines should guarantee hygienic packaging processes to protect product integrity. Investing in training for staff ensures they can effectively operate and maintain these machines, ultimately leading to improved productivity and reduced downtime.

**Tips:** Choose equipment that offers user-friendly interfaces and strong manufacturer support, enabling easier troubleshooting and maintenance. This can significantly reduce operational disruptions and enhance overall performance.

The Complete Guide to Mastering Food Packaging Machine Selection and Usage

| Key Consideration | Description | Impact on Business | Example Machine Types |

|---|---|---|---|

| Machine Type | Choose between vertical, horizontal, or semi-automatic machines based on your product and packaging needs. | Affects speed, efficiency, and the ability to handle various product sizes. | Vertical Form Fill Seal (VFFS), Horizontal Flow Wrapper |

| Production Volume | Determine your daily packaging needs to ensure the machine can meet the demand. | Inadequate volume capacity can lead to production bottlenecks. | High-speed packaging machines, Semi-automatic packaging machines |

| Type of Packaging Material | Consider the compatibility of the machine with different materials like plastic, aluminum, or paper. | Material compatibility affects cost and sustainability of packaging solutions. | Film Wrappers, Vacuum Sealers |

| Ease of Use | Look for machines that are intuitive for operators and easy to maintain. | Reduces training time and operational downtime. | User-friendly touch screen systems, Quick-changeover designs |

| Maintenance and Support | Consider the availability of parts and customer support for troubleshooting. | Can significantly reduce downtime and repair costs. | Manufacturers with local support, Extended warranty options |

| Budget | Evaluate your budget considering both acquisition and operational costs. | Directly impacts the scale and capability of the operation. | Entry-level machines, High-end automated systems |

Understanding Different Types of Food Packaging Machines and Their Applications

When it comes to the food industry, understanding the various types of food packaging machines is crucial for optimizing production efficiency and product quality. Different packaging machines are designed for specific applications, ranging from vacuum sealers that extend shelf life by removing air, to heat sealers that ensure secure closure of plastic pouches. Each type of machine has unique features and benefits, catering to diverse packaging needs in the food sector.

In addition to vacuum and heat sealers, there are automatic and semi-automatic filling machines that help streamline the packaging process for liquids, powders, or solids. For instance, liquid filling machines can handle everything from sauces to beverages, maintaining precision and minimizing spills. Similarly, vertical form-fill-seal machines are ideal for packaging snack foods or granular items, providing rapid production speeds while ensuring consistency in packing quantity and quality.

By selecting the right machine based on product type and packaging requirements, businesses can enhance their operational efficiency and ultimately meet consumer demands more effectively.

Cost Analysis: How Investing in Quality Packaging Machines Improves ROI

Investing in quality food packaging machines significantly enhances return on investment (ROI) by streamlining processes, reducing waste, and improving product shelf life. According to a report by Research and Markets, the global food packaging machinery market is expected to reach $41 billion by 2026, driven by advancements in automation and efficiency. Companies that prioritize high-quality machinery often report increased throughput, with some achieving productivity gains of up to 30%. This boost allows manufacturers to better meet consumer demand while minimizing labor costs.

Moreover, the longevity and reliability of top-tier packaging machines lead to reduced operational disruptions. A study by PMMI, the Association for Packaging and Processing Technologies, highlights that businesses utilizing reliable packaging solutions experience 20% less downtime compared to those employing lower-quality machines. By carefully analyzing the costs associated with machinery maintenance and the potential losses from downtimes or product spoilage, it's clear that quality packaging machines are an investment rather than an expense, ultimately enhancing profitability and market competitiveness.

Investment in Quality Food Packaging Machines vs. ROI

This chart demonstrates the relationship between the investment costs of various types of food packaging machines and their expected return on investment (ROI). As the quality of the machine increases, both the initial investment and the expected ROI also increase significantly.

Best Practices for Operating and Maintaining Food Packaging Equipment for Optimal Performance

Operating and maintaining food packaging equipment is crucial for ensuring optimal performance and product quality. First and foremost, regular inspection of the machinery is essential. Operators should conduct systematic checks on all components, including sealing mechanisms, conveyors, and sensors. This not only helps catch potential issues early but also enhances the longevity of the equipment. Moreover, maintaining a clean workspace and regularly cleaning the machine itself can prevent cross-contamination and downtime due to maintenance issues.

Training staff on best practices for operating the packaging machines is equally important. Employees should be well-versed in the machine’s operations, including how to identify and troubleshoot common problems. Implementing a structured maintenance schedule allows for timely interventions and can prevent unexpected breakdowns. Additionally, documenting all maintenance activities will aid in creating an efficient history log, which can be instrumental for future reference. By adhering to these best practices, businesses can ensure their food packaging equipment operates at peak efficiency, ultimately leading to higher productivity and better product shelf life.

Related Posts

-

Comprehensive Insights on Industrial Packaging Machines for Global Buyers

-

2025 Breakthroughs in Industrial Packing Machines: A Comprehensive Guide for Businesses

-

7 Essential Insights for Sourcing the Ideal Case Erector Machine Globally

-

Navigating Global Standards for Food Packaging Machines: A Comprehensive Guide to Export Certification

-

Revolutionizing Your Production Line with Innovative Industrial Packing Machines

-

5 Essential Insights for Maximizing Efficiency with Case Packer Machines