A-B-C Blog

Essential Checklist for Maximizing Efficiency with Your Box Taping Machine

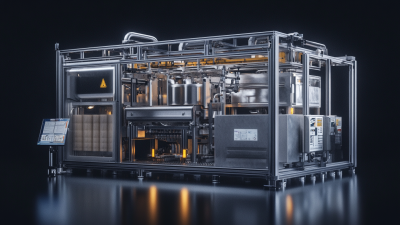

In today’s fast-paced packaging industry, the efficiency of operations is a crucial factor that can significantly impact overall productivity and cost-effectiveness. According to a recent report by the Packaging Machinery Manufacturers Institute (PMMI), companies that adopt advanced automation technologies, including the use of a Box Taping Machine, can increase their packaging throughput by up to 30%. However, despite the clear benefits of this essential equipment, many businesses still face challenges that hinder optimal performance. Common issues such as improper alignment, inconsistent tape application, and mechanical malfunctions can lead to time-consuming delays and increased operational costs. To address these problems effectively, it is essential to have a comprehensive checklist in place that maximizes the efficiency of your Box Taping Machine. By focusing on maintenance, training, and optimization strategies, organizations can not only enhance their packaging processes but also maintain a competitive edge in the market.

Understanding the Basics of Box Taping Machines for Optimal Use

When it comes to box taping machines, understanding the basics is crucial for optimal use and efficiency. A report from the Packaging Machinery Manufacturers Institute (PMMI) revealed that efficient packaging processes can lead to 20-30% reductions in operational costs. This significant savings underlines the importance of having a comprehensive grasp of how your taping machine operates, which can drive better performance and productivity.

To maximize the potential of your box taping machine, operators should focus on the machine's specifications, such as tape compatibility and speed settings. According to a study by Freedonia Group, the demand for automated packaging machines, including taping systems, is projected to reach $23 billion by 2025, reflecting the industry's shift towards automation and efficiency. Understanding these key features not only ensures proper setup but also enhances the lifespan of the equipment, thereby reducing the need for frequent repairs or replacements.

Moreover, regular maintenance and calibration are essential practices that can significantly impact the performance of the taping machine. According to a report by MarketsandMarkets, nearly 70% of manufacturers agree that preventative maintenance leads to fewer machine breakdowns and increased production uptime. Therefore, training staff in these foundational aspects will not only help operators utilize taping machines effectively but also contribute to overall operational excellence in packaging processes.

Key Features to Look for in a High-Efficiency Taping Machine

When investing in a high-efficiency box taping machine, there are several key features to keep in mind that can significantly enhance productivity. According to a report by Packaging World, companies that utilize automated taping solutions can improve their packaging speed by up to 40%. This increase in velocity directly correlates with higher output, allowing businesses to meet consumer demand more effectively.

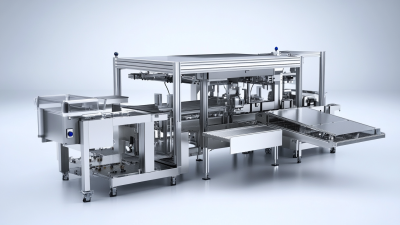

One essential feature to look for is adjustable tape tension. Machines equipped with this capability allow operators to customize the tension according to various box sizes and materials, leading to optimal sealing. Additionally, consider models with advanced sensors that detect box dimensions, ensuring precise tape application without excess tape waste. This not only conserves materials but also cuts operational costs significantly.

Tip: Regular maintenance of your taping machine can lead to longevity and sustained efficiency. Schedule routine checks to ensure components are functioning well, and replace worn-out parts promptly. Another valuable tip is to keep a quality tape stock on hand; using inferior tape may compromise the integrity of seals, ultimately slowing down the packing process and affecting product safety.

Maintenance Tips to Enhance the Longevity of Your Taping Equipment

Maintenance is crucial to ensuring the longevity of your box taping machine. Regularly inspecting and cleaning the equipment can prevent buildup that may cause wear and tear. Check the tape head for any residue or adhesive buildup, as this can affect the quality of the seal. Additionally, inspect the rollers and belts for any signs of fraying or damage, and replace them if necessary to maintain smooth operation.

Another important aspect of maintenance is proper lubrication. Use a high-quality lubricant on moving parts to minimize friction and reduce the risk of mechanical failure. Make it a habit to consult the manufacturer’s guidelines for specific lubrication intervals. Maintaining the correct tension on the tape and ensuring consistent feed rates will also enhance the efficiency and lifespan of your taping machine.

Lastly, conducting regular training sessions for your team on the proper use of the machine can greatly influence its longevity. Proper calibration and handling not only enhance efficiency but also reduce the chances of mishandling that could lead to damage. By fostering a proactive maintenance culture, you can ensure your taping equipment operates at peak performance for years to come.

Setting Up Your Workstation for Maximum Box Taping Productivity

To maximize productivity with your box taping machine, setting up an efficient workstation is crucial. According to a report by the Packaging Machinery Manufacturers Institute (PMMI), improper workstation layout can reduce operational efficiency by up to 30%. By organizing your workstation with a focus on ergonomics and workflow, you can significantly increase your output and decrease any potential downtime.

Start by positioning your tape dispensers and box sealing machines within easy reach. A study from the Institute of Industrial Engineers emphasizes that optimizing workspaces for minimal movement can lead to a 15% increase in productivity. Ensure that your taping equipment is at the right height to reduce strain and facilitate quick access. Additionally, label all materials and tools clearly to streamline the packing process.

By implementing these strategies, not only can you enhance the overall efficiency of your operations, but you can also maintain a safer and more organized work environment, which is paramount given that workplace injuries can lead to significant costs for businesses in the packaging sector.

Common Mistakes to Avoid When Using Box Taping Machines for Packaging

When it comes to optimizing packaging processes, using a box taping machine can significantly enhance efficiency. However, operating these machines comes with a set of common pitfalls that can hinder productivity. According to a report by the Packaging Machinery Manufacturers Institute (PMMI), improper machine setup and maintenance accounts for up to 30% of machine downtime in packaging operations. Not adhering to the manufacturer's guidelines for tape thickness and box size can lead to misalignment issues, which could cause frequent jams and increase the total cost of packaging.

Another common mistake is neglecting regular maintenance, which is crucial for ensuring smooth operation. A study by the Association for Packaging and Processing Technologies (PMMI) indicates that companies that implement a proactive maintenance schedule can reduce equipment failure by as much as 25%. Additionally, operators should be trained comprehensively on the correct usage of taping machines. Lack of training can lead to inefficiencies, with up to 40% of packaging errors stemming from operator mistakes. Paying attention to these common errors can drastically improve operational efficiency and maximize the utility of your box taping machine.

Efficiency in Box Taping Machines: Common Mistakes and Best Practices

Related Posts

-

Envisioning Tomorrow: The Evolution of Case Erector Machines in Packaging Industries

-

Comprehensive Insights on Industrial Packaging Machines for Global Buyers

-

Navigating Global Standards for Food Packaging Machines: A Comprehensive Guide to Export Certification

-

Exploring the Versatile Applications of the Best Depalletizer Machine in Various Industries

-

Mastering the Art of Containers and Packaging Strategies for Sustainable Business Growth

-

Advantages of Using Box Taping Machines for Efficient Packaging Solutions