A-B-C Blog

Innovative Options for Food Packaging Equipment That Transform Your Production Line

Efficiency and effectiveness in food packaging equipment help to determine the success of a food brand in today's world of fast food production. As businesses try to keep up with changing consumer demands, there is a more pressing need than ever for revolutionary solutions in food packaging, from sustainability to automation. Redefining the way a product is packaged by making it not only well guarded but also more alluring to the eye is what technology advancement brings. It will be examining innovative options in food packaging equipment that transform production lines and give an advantage to manufacturers.

Modern consumers know very well how the impact of package affects the environment and thus are conditioned to putting pressure on companies to do more about wiser and greener methods of working. For example, intelligent packaging systems are the type of technology that includes sensor and smart technology, which could be adapted as part of food packaging machinery for today. Production lines replete with these technologies create less spoilage and elongate the life of the freshness of products while satisfying the discriminating consumer. Explore with us the latest trends in and technologies for food packaging equipment that you should consider for transforming your processes and thereby elevating your brand.

Revolutionizing Food Packaging: The Role of Smart Technology

Smart technology integration is radically transforming the food packaging industry. As per a report by MarketsandMarkets, the global smart packaging market is expected to reach USD 41.7 billion by 2027, at a CAGR of 6.2%. This growth is primarily attributed to advancements such as IoT-enabled devices, artificial intelligence, and automated solutions for improved operational efficiency and product safety. Smart technology in food packaging equipment provides real-time data tracking for manufacturers to monitor the freshness and quality of products throughout the supply chain. For instance, temperature and humidity fluctuation sensors can warn companies when products are about to spoil or get contaminated. This is highly useful, as it ensures consumer safety, while also enabling businesses to minimize waste and cut costs. A recent study by the Food Waste Reduction Alliance shows that improvements in packaging strategies could lead to any potential reduction of food waste by up to 30%, thus providing further environmental and economic advantages for such innovations. Automated packaging solutions also render production lines more efficient. The International Society of Automation reports that over 70% of food manufacturers have initiated automation technology adoption aimed at improving their packaging processes. This change not only accelerates the manufacturing process but also provides greater flexibility in offering packaging designs that allow for changing consumer preferences. By upgrading their food packaging machinery, these manufacturers have positioned themselves to meet sustainability and efficiency demands in the food industry.

Eco-Friendly Packaging Solutions for Sustainable Practices

The fast-changing world makes it very hard for an industry like the food industry to move toward sustainable practices. Eco-friendly packaging is therefore leading light and changing the way products are packaged for the environment and otherwise. Innovative food-packaging technologies are enabling companies to move from synthetic, petroleum-based materials to biodegradable, compostable, and recyclable materials, thereby reducing their environmental footprint. These advances can also help to keep products fresh and attract environmentally concerned customers.

Among the more important trends in eco-friendly packaging is the use of plant-based materials. Unlike the conventional plastics, these biodegradable alternatives decompose naturally over time and so help reduce piling wastes in landfills. Furthermore, environmentally safe water-based inks and adhesives are also being used in packaging by companies, thus going one step further to ensure sustainable practices. Such packaging solutions installed on the production line help reinforce the brand image and contribute to a green planet.

On the other hand, advances in packaging technology have brought about better preservation methods. Vacuum packaging, modified atmosphere utilization, and other cutting-edge innovations prolong food products' shelf life without compromising their quality. This not only decreases food wastage but also satisfies increased consumer demand for quality and freshness of long-living items. Investing in modern eco-friendly packaging systems gives the business an opportunity to better organize its production and embrace environmental sustainability.

Streamlining Production Lines with Automated Packaging Systems

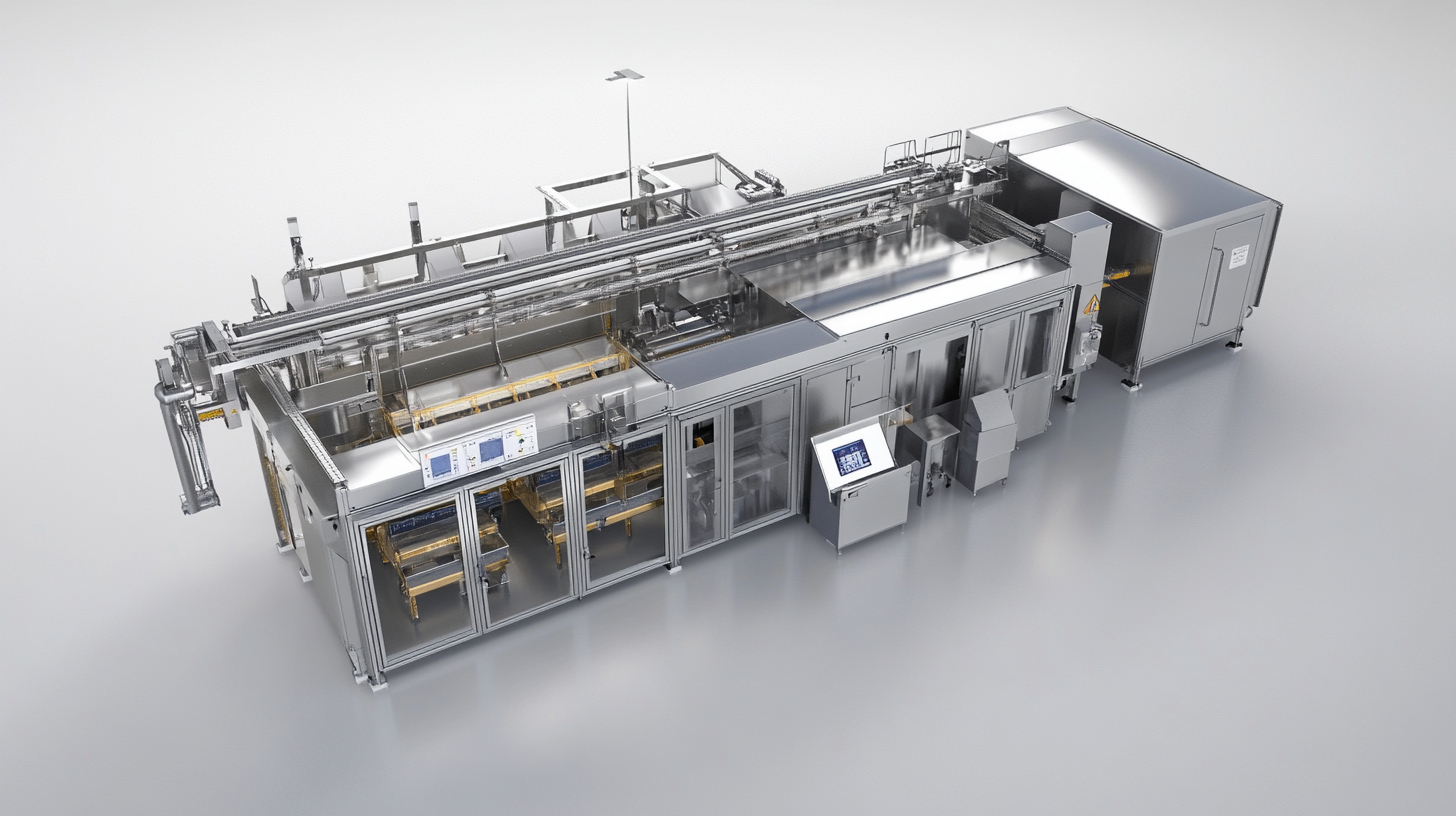

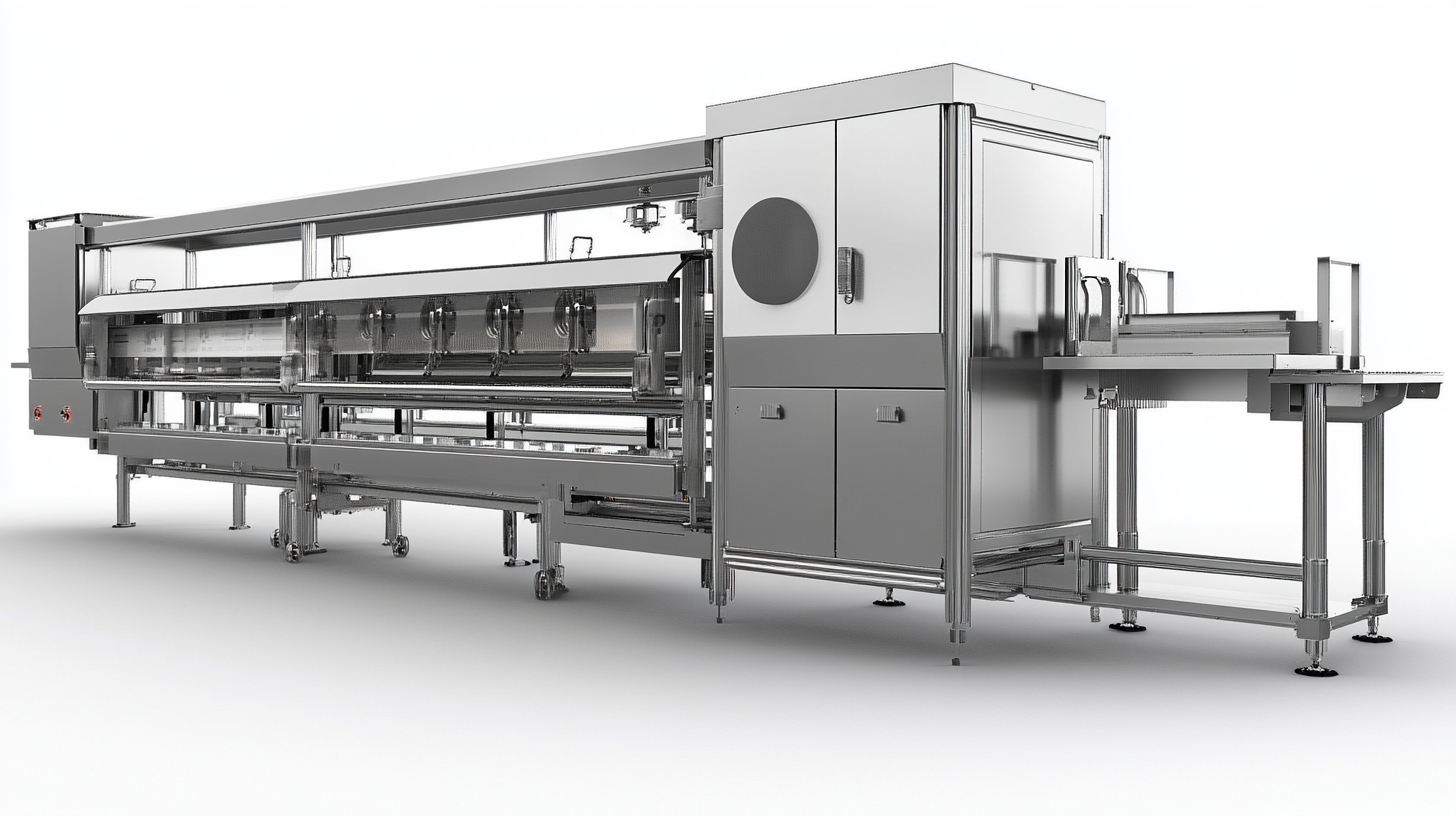

Due to their inherent advantages of efficiency and consistency, automated packaging systems are really gaining priority in modern production lines. As reported by Smithers Pira, the global automated packaging solutions market is expected to grow at a compound annual growth rate of 14%, reaching $65 billion by 2025. This growth is an indication of a wider trend in the industry, whereby manufacturers aim to use their technical innovations in order to cut down on labor costs and increase productivity.

Streamlining production lines is not only about operational costs; it is also about enhancing the quality of the end product. Advanced packaging systems utilize technologies such as robotics, artificial intelligence, and machine learning to provide high accuracy in packaging while minimizing errors. PMMI says that 70% of manufacturers embracing automation have improved product quality and reduced waste. This integration enables companies to realize maximized speed in their desired packaging, keeping their products fastened in the most secure way.

With strong consumer demand for sustainable products, automated systems are being designed that can handle ecologically friendly packaging materials. The research made by Freedonia Group indicates that from 2021 onwards, the demand for sustainable packaging practices is anticipated to rise significantly, influencing choices made in production line equipment. Investing in automated packaging also enhances production line efficiency and brings companies in line with the modern consumer expectation toward sustainability, hence being an attractive option for manufacturers ready to innovate.

The Impact of Customization in Food Packaging Equipment

In the fast-paced food industry of today, customization matters concerning food packaging equipment. When packaging processes can be customized, operational efficiency skyrockets while product and employee security is amplified. With companies trying harder than ever to satisfy diverse consumer demands, newer technologies come into play, thus increasing packaging flexibilities. For example, the advent of no-code software tools allows manufacturers to modify robotic programming with little effort thereby greatly easing the task of automating production lines.

One other advance in packaging design tools that supports this trend are online configurators that allow packaging designs to be created without the need for complex software development. This shortens the pathway for brands to design and prototype new packaging ideas. This less cumbersome means of customization will lead to quicker market responses and alignment with consumer demands.

The emergence of the packaging machinery market speaks to the need for innovation to keep pace with industry demands. As businesses look to improve efficiency and cut costs, smart technology integration into equipment for food packaging is becoming a requirement. With the projected growth of over 7.3% in the years to come, customizable packaging options will truly be at the forefront of defining the future of food production and distribution.

Emerging Trends: Innovative Materials in Food Packaging Solutions

Today's fast-paced world of food packaging has witnessed innovative materials taking the lead in setting modern production lines to meet consumer needs. The lightest aluminum cans in the world, newly developed, heighten the convenience of use while lengthening the shelf life by a factor of seven. Such efforts combine function and sustainability and clearly show that the designs in packaging go beyond mere protection of the product to enhancing brand value and user experience.

With the shift in consumer choices towards more portable solutions, the food and beverage packaging segment is poised for significant growth. The sector is currently valued at over $222.1 billion by 2024, with nearly 4.7 percent growth as a CAGR, driven by increased consumer demand for convenience and ready-to-eat products. Food service packaging starts its upward climb, too, as forecasts for the market point to a growth propelled by similar consumer needs. These increase the significance of adopting new materials for easier usage yet more sustainable uses.

Additionally, development progresses in paper packaging technology in terms of biodegradable coating and water-resistant treatments. The innovations provide an important step in environmentally friendly solutions. Apart from answering the call for more sustainable practices, these innovations are about contemporary functional demands in packaging. The focus is now placed on how upcoming trends promise to make great impacts on food packaging on convenience and environment concerns, as the industry gears up for major shows such as swop 2024, Shanghai.